Gypsum casting powder has a varied set of applications as per the performance factor. In a clean, dry jar, it is combined with water and stirred for 2 to 3 minutes. Gypsum casting powder is a naturally occurring mineral that may be found in deposits throughout the country. It starts as a soft, white mineral rock that is ground into a dry powder. To minimize the setting time of gypsum casting powder, retarders such as organic acids, soluble salts, basic phosphates, and proteins are utilized. Hardeners can also be used to improve the strength and non-brittleness of gypsum plaster..

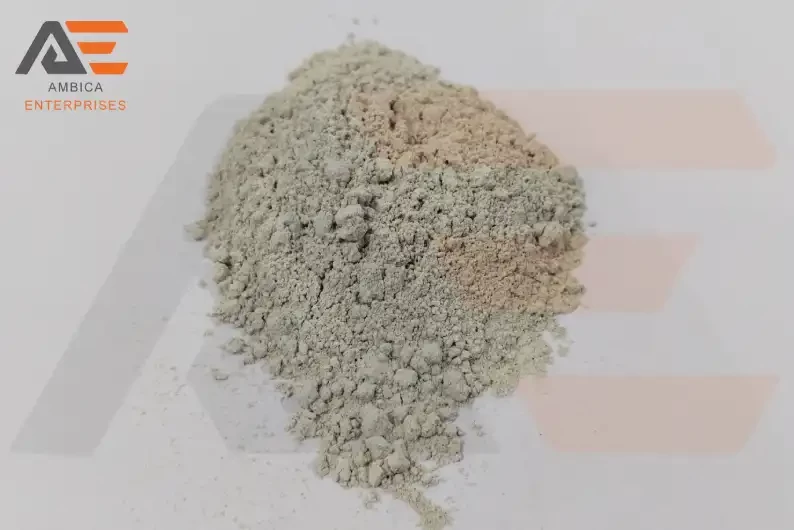

Gypsum stone is heated, crushed, and ground into powder to create gypsum casting powder, which is a white powder. The gypsum board powder produced has a wide range of uses in the building, agricultural, and food sectors.

Due to its great fire resistance, gypsum casting powder can be used to build a fire-resistant barrier in front of steel. Around 70% of the noise in the surroundings may be captured by gypsum casting powder. Universal gypsum powder is readily available and may be purchased at a reasonable cost. Because gypsum plaster can be readily molded and aged into any desired shape, it is used to create a variety of sculptures. It’s used to make ornamental items and may be molded into a variety of forms.

Gypsum Powder Manufacturers in India

We are well-known gypsum powder manufacturers in India and other countries. Despite our limited resources, we can quickly produce high-quality gypsum casting powder. A gypsum powder for plants is straightforward to set up. Sand cement plaster takes 20–21 days to firm up, dry, and settle. Continue to add or spritz water while executing this strategy before going on to the next stage. Fused quartz sand is another prolific product produced by us which itself can account for hard surfaces with gypsum powder.

White gypsum powder (Calcium sulfate Dihydrate/ Hydrous Calcium Sulfate) is manufactured from gypsum powder plaster, whereas gypsum powder is made from gypsum stone. This powder has a wide range of uses and industries. Gypsum powder manufacturers respond to such requests. Foods containing gypsum powder are likewise quite popular among us.

Gypsum is utilized to generate the right forms for a variety of styles and settings. It is commonly used as a design element by interior designers. We also manufacture thermal spray bronze wire which is used for the coating of the respective product after the required action of gypsum powder. Gypsum is widely used used in the construction sector. Gypsum has several applications. One of the most important components is the design of drywall that is simple to install using gypsum powder.

The plaster of Paris texture is created by combining water and powder. Micronized gypsum powder is coveted for its ability to insulate against heat and fire. Several plaster ceilings from Paris have been fitted. The paste is applied to slabs and molded into the desired form to produce drywall.

Gypsum Powder Price

The gypsum powder price is influenced by quality control methods, shipping costs, and service fees. We produce gypsum powder in India and frequently supply in large quantities. Another prolific product produced by us is copper slag which can be incorporated into hard surfaces with gypsum powder price. Gypsum powder is a mineral that may be found in several different deposits throughout India. We make high-quality gypsum in a very fine grade.

Since then, gypsum powder price has become increasingly important. These concerns have a substantial influence on the gypsum powder price. Modern technology has improved the mechanical and physical features of gypsum and gypsum-based products, such as durability and endurance. Thermal spray babbitt wire is another product we make. You may also use it to paint quickly and effectively. It’s useful since it saves time while being effective.

Gypsum Casting Powder Benefits

Gypsum powder has grown increasingly essential since then. The mechanical and physical properties of gypsum and gypsum-based products, such as durability and longevity, have increased thanks to modern technology. It is advantageous since it reduces time while yet providing adequate wall coverage.

The smooth, white surface of universal gypsum powder is devoid of scars and cavities. They’re fireproof, environmentally friendly, and provide acoustic and thermal insulation. They are also beneficial to people’s health. As a consequence, the demand for Gypsum Powder manufacturers is enormous.

Gypsum Casting Powder Uses

When it comes to construction, gypsum is a widely used substance. The creation of drywall that is easier to create using plaster gypsum powder is one of the most significant factors. Water and powder are mixed to make the plaster of Paris texture.

Drywall is made by applying the paste to toon slabs and molding them into the appropriate shape. Gypsum powder that has been finely ground is highly valued for its ability to insulate against heat and fire. Several artificial ceilings are made of plaster of Paris. Farmers frequently use micronized gypsum powder to remove thick clay and subsurface layers from their gardens and fields. They are commonly used by farmers in their gardens and fields to remove thick clay and subsurface layers. Regular quartz sand is another popular product we provide. Its goal is to enhance the general composition of the soil and promote root development. Zinc aluminum wire produced excellent results of coating on the respective surfaces after abrasion.

It helps to conserve soil and water while also decreasing soil erosion. Gypsum casting powder is a popular second-hand option. The physical characteristics of cement cause it to harden more slowly. We also create a fine quality fused quartz sand. Boral gypsum powder creates the basic shapes for varied patterns and ambiances. Interior designers frequently use it as a design element.